Keeping Hydropower Flowing: Emergency Gate Valve Repair

When a nearly century-old secondary control gate valve failed at one of the nation’s leading hydroelectric power providers, urgent action was required. The malfunctioning 6,500 lb. actuating assembly was vital to operations. With no time to lose, Thompson’s Hydro Consulting & Maintenance Services (HCMS) called in CMMC to help deliver a timely, high-performance solution.

CHALLENGES

The components age, scale, and complexity made this a unique repair. With a tight timeline and a critical function on the line, the team needed to quickly reverse-engineer and rebuild major components, all while ensuring strength, durability, and precise fit.

SOLUTION

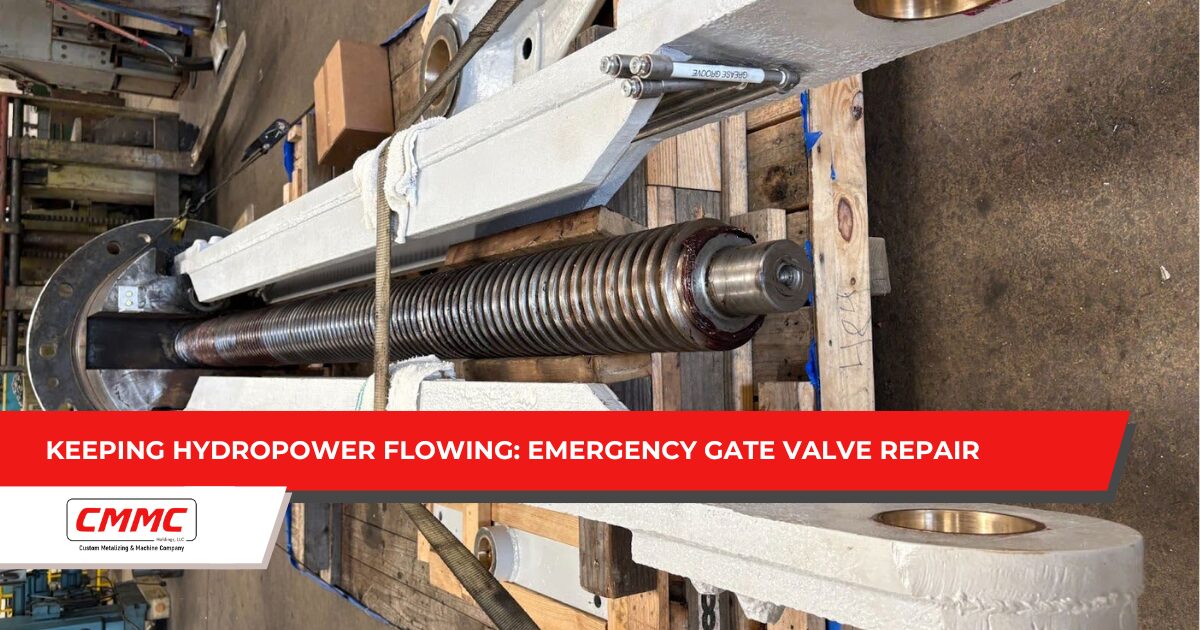

CMMC collaborated with Thompson’s HCMS and the client’s engineers to develop a complete repair plan. The lead screw was restored and the crosshead rebuilt using a custom aluminum bronze insert, threaded inside and out, with a new lube port added for ongoing maintenance. Pivot points were rebuilt with new pins and sleeves, arms were blasted and epoxy-coated, and lube lines were replaced. The unit was fully reassembled, and the HCMS team completed the final installation.

RESULTS

In about a week, the repaired assembly was back in place, restoring full function and avoiding prolonged downtime. The collaboration delivered a strong, functional, and timely solution to a critical equipment failure.

CMMC is your trusted partner for emergency reverse engineering and precision rebuilds of large-scale, mission-critical components. With advanced fabrication equipment and a team of highly skilled fabricators, we have a proven track record of success, serving industrial facilities across the Southeastern United States. We understand the critical nature of your needs and are dedicated to providing unparalleled value. Our ISO certification ensures the highest quality standards, guaranteeing your satisfaction and success. Give us a call at 803-464-7489 or email us at info@cmmcsc.com to learn more.